2022 recommended pre-emergence nozzles

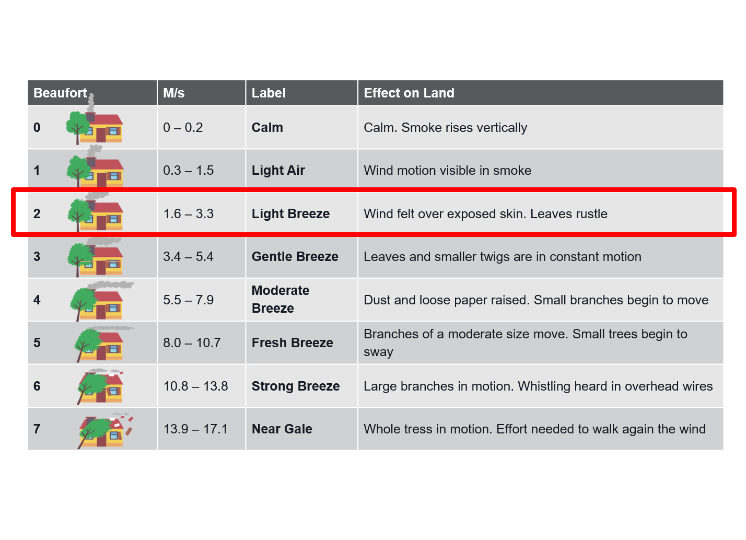

Weather

The biggest influence on drift is the wind speed, ideal wind conditions are force 2 on the Beaufort scale. Higher speeds can cause spray to be carried away from its target. Avoid spraying in completely still conditions which could cause spray to hang in the air. Double the wind speed; double the drift.

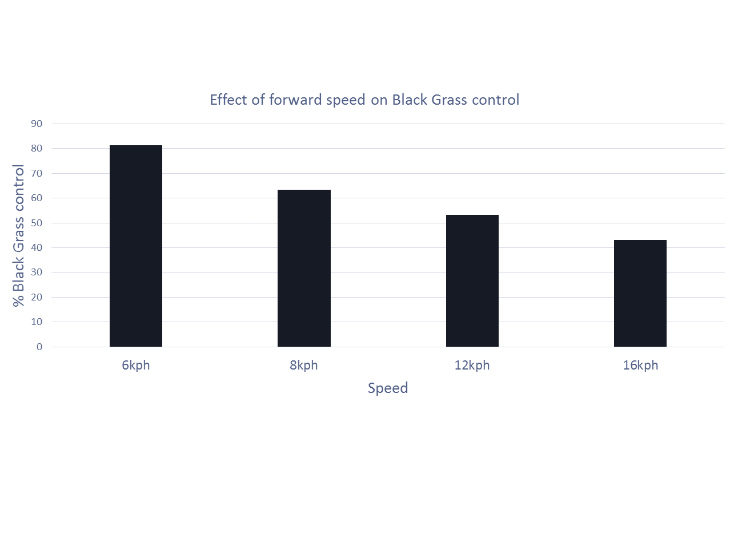

Forward speed

Excessive speeds can lead to decreased boom stability and create turbulence behind the boom, which may lead to increased drift and reduced product efficacy. The optimum speed for applying pre-emergence herbicides in 2016 trials was below 12 kph, this delivered the best balance of work rate and efficacy.

Boom height

With a steady forward speed, the next step is to ensure correct boom height. In trials reducing the boom from 100cm above the crop to 50cm efficacy went up from 70% to 87% control. To aid stable and correct boom height ensure correct tyre pressure, grease the boom suspension, lubricate bushes and bearings and check wear, attach a Syngenta cable tie to the boom which guides 50cm boom height, set-up sensitivity of boom-levelling system for minimal drift.

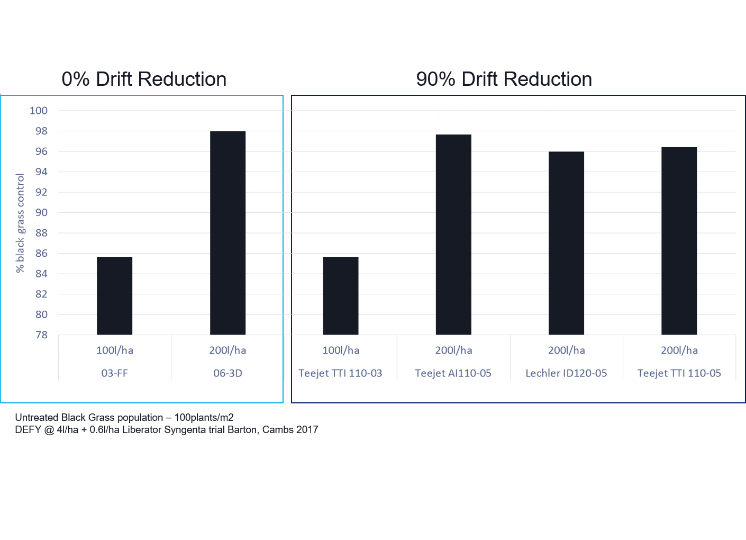

Nozzles

Coarse to extra coarse droplet size will reduce drift further. Current application work has shown strong performance from 90% drift reduction nozzles, proving drift reduction doesn’t have to compromise efficacy.